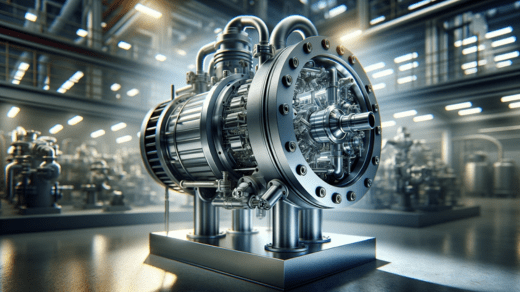

The world of industrial machinery is constantly evolving, with innovative technologies driving efficiency and productivity. One such innovation is the side channel vacuum pump. In this article, we will delve into the intricacies of this remarkable piece of equipment, exploring its inner workings, applications across various industries, and the advantages it offers. Join us on a journey to uncover the potential of the side channel vacuum pump.

1. What is a Side Channel Vacuum Pump?

The Side Channel Vacuum Pump is a versatile and powerful machine used for creating a vacuum in various industrial applications. Unlike traditional vacuum pumps, this technology operates on a different principle, making it highly efficient and reliable.

2. How Does It Work?

The Side Channel Vacuum Pump operates by utilizing the side channel effect. It generates vacuum through a series of impellers that rotate within a side channel. As the impellers spin, they create a centrifugal force that draws in air or gas, resulting in a vacuum. This unique mechanism ensures consistent performance and reliability.

3. Key Features

- Efficiency: The Side Channel Vacuum Pump is known for its high efficiency, making it a cost-effective choice for many industries.

- Low Noise: It operates quietly, reducing noise pollution in the workplace.

- Compact Design: Its compact size allows for easy installation, even in limited spaces.

- Minimal Maintenance: With fewer moving parts, it requires minimal maintenance, saving both time and money.

4. Applications

The Side Channel Vacuum Pump finds applications in various industries, including:

- Packaging: Used for vacuum packaging of food and other products.

- Medical: Essential for medical equipment such as dental suction units.

- Environmental: Used in wastewater treatment plants to handle liquids and solids.

- Automation: An integral part of automated systems for material handling and pick-and-place operations.

5. Advantages of Using a Side Channel Vacuum Pump

- Energy Efficiency: It consumes less energy compared to other vacuum pump types, contributing to cost savings.

- Versatility: Its ability to handle different gases and liquids makes it suitable for a wide range of applications.

- Reliability: The unique design results in minimal wear and tear, ensuring long-term reliability.

- Low Maintenance: Reduced maintenance requirements mean less downtime and higher productivity.

6. Why Choose a Side Channel Vacuum Pump?

When considering a vacuum pump for your industrial needs, the side channel vacuum pump stands out for several reasons:

- Cost-Effective: It offers a compelling return on investment due to its efficiency and durability.

- Environmental Friendliness: Its low energy consumption aligns with eco-friendly practices.

- Quiet Operation: Ideal for work environments where noise reduction is essential.

- Versatility: Its ability to handle diverse applications makes it a versatile choice.

7. Side Channel Vacuum Pump in Action

Let’s take a closer look at how this technology performs in real-world scenarios. Whether it’s ensuring the freshness of your packaged food or facilitating critical medical procedures, the Side Channel Vacuum Pump plays a crucial role in various industries.

The Side Channel Vacuum Pump has proven itself as an indispensable technology across various industries. Its unique operating principle, efficiency, and reliability make it a top choice for businesses looking to enhance their operations. Whether you’re in packaging, healthcare, or any other sector, consider harnessing the power of the Side Channel Vacuum Pump to streamline your processes and boost productivity.