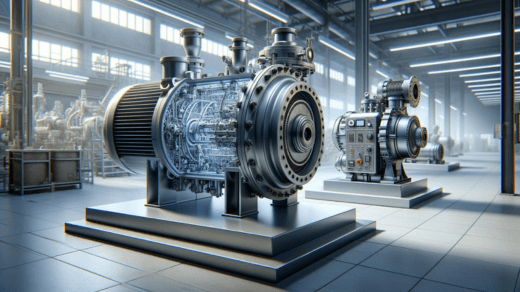

Side channel vacuum pumps are innovative devices that play a crucial role in various industrial, environmental, and medical applications. Unlike traditional vacuum pumps, side channel vacuum pumps, also known as dry vacuum pumps, offer enhanced efficiency, reliability, and versatility. In this article, we delve into the intricacies of side channel vacuum pump technology, its working principles, applications, advantages, and more.

Understanding Dry Vacuum Pump Technology

Dry vacuum pumps, as the name suggests, operate without the need for lubrication or any kind of liquid sealant. This distinguishes them from oil-sealed vacuum pumps, making them ideal for applications where oil contamination is a concern. Side channel vacuum pumps utilize a unique mechanism to generate vacuum efficiently, making them suitable for a wide range of challenging environments.

Applications of Side Channel Vacuum Pumps

Side channel vacuum pumps find extensive usage across various industries due to their versatility and reliability. They are commonly employed in industrial processes such as packaging, pneumatic conveying, and printing. Additionally, these pumps play a vital role in environmental applications like wastewater treatment and air sampling. Moreover, in the medical field, side channel vacuum pumps are utilized in devices such as medical aspirators and dental suction units.

How Side Channel Vacuum Pumps Work

At the heart of a side channel vacuum pump lies the principle of regenerative centrifugal force. As the impeller rotates, it creates multiple channels where air or gas is accelerated and compressed. This continuous compression generates a vacuum, drawing in more air or gas until the desired pressure level is achieved. The absence of lubricants ensures clean and oil-free operation, making side channel vacuum pumps suitable for sensitive applications.

Advantages of Side Channel Vacuum Pumps

One of the key advantages of side channel vacuum pumps is their ability to operate without oil or water, eliminating the risk of contamination. Furthermore, they offer consistent performance across a wide range of pressures and flow rates. Their compact design and minimal maintenance requirements make them cost-effective solutions for various industrial needs. Additionally, side channel vacuum pumps are known for their quiet operation and energy efficiency.

Limitations and Considerations

While side channel vacuum pumps offer numerous benefits, it’s essential to consider their limitations. These pumps may not be suitable for applications requiring extremely high vacuum levels. Additionally, the presence of solid particles or liquids in the pumped gas may affect their performance and longevity. Proper filtration and regular maintenance are necessary to ensure optimal operation.

Maintenance and Care Tips

To prolong the lifespan of a side channel vacuum pump, regular maintenance is crucial. This includes inspecting and cleaning the pump components, checking for leaks, and ensuring proper lubrication of bearings if applicable. It’s also essential to monitor operating parameters such as temperature and pressure to prevent overheating or excessive wear.

Comparison with Other Vacuum Pump Types

In comparison to traditional vacuum pump types such as rotary vane pumps or liquid ring pumps, side channel vacuum pumps offer distinct advantages. They are more compact, quieter, and environmentally friendly. Moreover, their dry operation eliminates the need for oil changes or disposal, reducing overall operational costs.

Choosing the Right Side Channel Vacuum Pump

When selecting a side channel vacuum pump for a specific application, several factors must be considered. These include the required vacuum level, flow rate, operating conditions, and environmental factors. Consulting with a knowledgeable supplier or engineer can help ensure the right pump is chosen for optimal performance and efficiency.

Innovations in Dry Vacuum Pump Technology

Advancements in dry vacuum pump technology continue to drive innovation in various industries. New materials, designs, and manufacturing techniques are improving pump efficiency, reliability, and longevity. Moreover, integration with smart sensors and control systems enables remote monitoring and predictive maintenance, minimizing downtime and optimizing productivity.

Case Studies and Success Stories

Numerous case studies demonstrate the effectiveness of side channel vacuum pumps in real-world applications. From automotive manufacturing to semiconductor production, these pumps have proven their reliability and efficiency in diverse industries. Success stories highlight how businesses have benefited from the adoption of Dry Vacuum Pump technology, achieving cost savings and process improvements.

Future Trends in Side Channel Vacuum Pump Development

Looking ahead, the future of side channel vacuum pump development is promising. Continued research and innovation are expected to lead to even more compact, energy-efficient, and environmentally friendly designs. Integration with Industry 4.0 technologies and the Internet of Things (IoT) will enable predictive maintenance and optimization, further enhancing the value proposition of these pumps.

Environmental Impact and Sustainability

One of the significant advantages of side channel vacuum pumps is their minimal environmental impact. By eliminating the need for oil or water, they reduce the risk of pollution and contamination. Furthermore, their energy-efficient operation helps minimize carbon emissions, contributing to sustainability efforts in various industries.

In conclusion, side channel vacuum pumps represent a significant advancement in vacuum pump technology. Their dry operation, compact design, and versatility make them ideal for a wide range of industrial, environmental, and medical applications. With ongoing innovation and development, these pumps will continue to play a vital role in driving efficiency, reliability, and sustainability across diverse sectors.